AUS10 vs VG10 – Which Knife Steel To Choose?

People frequently forget to check the quality of knives before buying. They tend to believe that steels are the same in every knife, but it’s not true.

Here, AUS10 vs VG10 is a great example where it seems similar, but they are not. There are numerous differences that have been shown throughout this write-up.

Differences can be found everywhere, including in toughness, hardness, sharpening, edge retention, and rust resistance.

Even though they are the best steel, they have some strong and weak points as well. We’ve also elaborated that thoroughly in this article.

For those who are concerned about the cost of this steel, we discussed that in the final section.

AUS10 vs VG10 – What’s The Difference?

Both knives are popular Japanese steels. They both are the best quality materials. But you’ll see there is a significant amount of difference between these two knife steels.

In VG 10 they have used the best quality cutlery grade stainless steel. So most people prefer the VG10.

But it doesn’t mean they are the best; it has been observed that AUS10 provides an even more smooth-cutting experience.

So here, we will try to take the anecdotes out of it. In addition, we will try to show all the insights between AUS10 and VG10 steel knives.

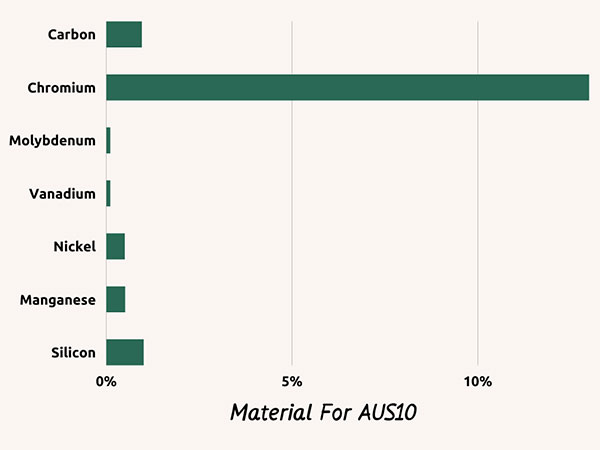

Materials

Tokyo-based Aichi steel is the main material for AUS10. This material holds materials like –

- Carbon: 0.95-1.10%

- Chromium: 13.0-14.5%

- Molybdenum: 0.10-0.31%

- Vanadium: 0.10-0.27%

- Nickel: 0.49%

- Manganese: 0.50%

- Silicon: 1.00%

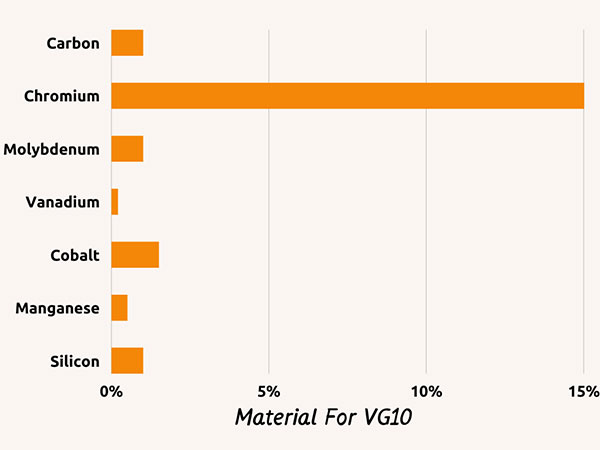

VG10, on the other hand, has a High Rupturing Capacity (almost 61 HRC). The materials VG10 uses –

- Carbon: 1.00%

- Chromium: 15.00%

- Molybdenum: 1.00%

- Vanadium: 0.20%

- Cobalt: 1.50%

So you can expect the best edge-retention functionality with the high corrosion resistance factor.

Durability

AUS10 can be considered a rock-solid knife because of its HRC 60 results. 60 to 62 HRC points range indicates a tough material.

So the material of the blade will be top-notch and it will give protection against any kind of external force. Other than that, the existence of 0.28% vanadium overstates the overall toughness.

Vg10 also falls in this range holding a 61 HRC point. So you will get even a little better outcome from VG10 than AUS10 in terms of toughness.

Along with that, the materials of VG10 have high abrasion and corrosion characteristics for its carbon components.

Furthermore, 1 to 1.20 percent molybdenum contributes to the hardness of this knife.

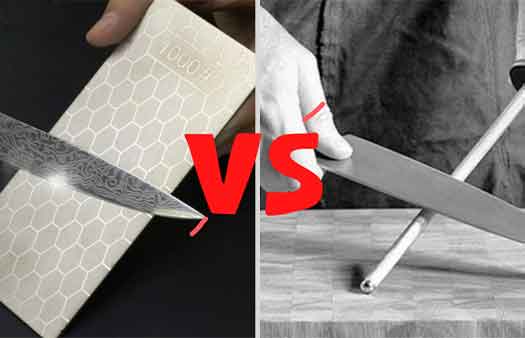

Edge Retention And Sharpening

AUS10 has excellent edge retention, but it lags behind VG10. The lack of carbon and vanadium properties is the reason behind it.

Because of its poor edge retention, it needs to sharpen consistently. otherwise, the expected outcome won’t be achieved.

VG10 has outstanding edge retention because of its high percentage of carbon (1.05) and vanadium (0.29) properties. Other than that, carbide keeps the edge sharp for a longer time.

Therefore, repeatedly sharpening the knife is not necessary here.

Corrosion And Wear Resistance

Your knife’s main protection against corrosion and wear comes from chromium, nickel, and vanadium.

Since the combination and proportion of these substances are perfect in AUS10, your knife will be well protected.

You can expect almost similar types of results from the VG10 too. The reason is that VG10 also has the same properties in the ideal proportion.

Here, the only problem is that the VG10 knife won’t be rustproof. So you are not allowed to wash it with a dishwasher.

Try to keep it dry and clean. Use oil when needed.

Sharpness

In terms of the sharpness of the blade, both are outstanding. A knife’s sharpness is largely determined by the quality of the steel.

Here AUS10 and VG10 are both the best in their industry.

But when it comes to the sharpening process, you will see some differences. VG10 gives you a sharp edge in just a few seconds of sharpening. For AUS10, you will need more time because of its poor edge retention.

The Cost Difference Between AUS10 vs VG10

When it comes to the price, AUS10 offers a much lower price than VG10.

Both the knife prices started from $30 to $40. AUS10 mid-range knives cost $70 to $120. Although the price depends on multiple factors, most of the knives of AUS10 fall in this range.

VG10, on the other hand, is a bit more expensive than other midrange knife steel. The price here starts at $70, but it reaches $200 at the end.

Additionally, both of them have knives in the elite category. Generally, this range begins at $180 or $200 and crosses $400 at the highest point.

AUS10 vs VG10: Advantages And Disadvantages

Even though both of these steels are equally great, each has its strengths and weaknesses as well.

Let’s see their advantages and disadvantages shortly.

Advantages Of AUS10

- Tough Steel: AUS10 has all the necessary components in its steel, so it has both toughness and hardness.

- Corrosion, wear, and rust resistance: AUS10 has all the resistance components.

- Quick sharpen: Because of its great edge retention, AUS10 can sharpen pretty quickly.

- Affordability: Quite cheaper than VG10.

Disadvantages Of AUS10

- Lack of necessary components: Cobalt is absent, which limits other features.

Advantages Of VG10

- Super hardness: Cobalt and manganese provide great hardness in them.

- Lightweight: Compared to AUS10, VG10 is lighter in weight.

- Sharpness: VG10 has an excellent sharp blade.

Disadvantages Of VG10

- Not rust resistance: Since VG10 is not rust-resistant, life expectancy is lower.

- Expensive: It’s a bit costly compared to other similar products.

Conclusion

We believe that you understand the main difference between AUS10 vs VG10 in this write-up.

Knives’ abilities are largely determined by the quality of steel. Though both of these steels are great, there are some slight differences between them.

We started with the main difference between AUS10 and VG10 steel.

In that section, the main differences between these two steel are shown in the following four points:

- Material

- Durability

- Edge retention

- Sharpness

- Corrosion Resistance

Later, we spoke about how much these two steel products cost from multiple perspectives.

Finally, we wrapped this up by discussing the advantages and disadvantages of these steels.