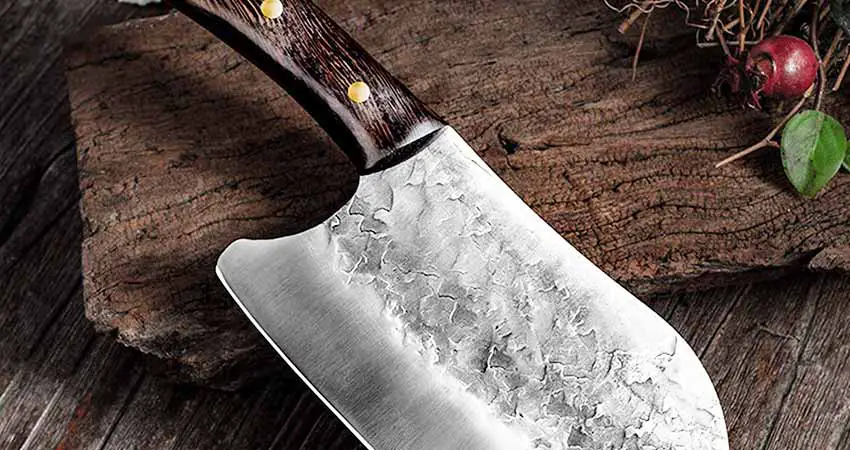

Is Serbian Knife Handmade?

Have you ever gone window shopping at a custom cutlery shop and got your eyes glued to some cutlery and wondered; is the serbian knife handmade or forged?

To your surprise, Serbian knives are handmade. Most of them are made by blacksmiths using carbon steel metal which is durable and can be shaped into a thin sharp blade.

By the knife’s appearance, it’s hard to tell the nature of the blade, leave alone whether it is forged or handmade.

Reading this article? You are on the right path to understanding how to make Serbian knives with ease

Is A Serbian Knife Handmade?

Yes. The Serbian knife is handmade.

Are you wondering how such a blade can be handmade? Worry no more as I am taking you through a step by step process of how to make a handmade serbian knife.

Materials required to forge a Serbian knife –

- Cutting blade

- Cylindrical scrap carbon steel metal

- Metal tongs

- Meter rule and marker

- Drilling machine

- Piece of wood

- Vices and clamps

- Hammers

What Is A Serbian Handmade Knife Making Process?

Making a Serbian knife may look like a complicated task, but using the above-listed materials and tools, making the Serbian knife gets easier and faster.

Below is a guide step by step on how to forge a handmade serbian knife.

Step 1: Finding a Suitable Material

Not every scrap metal is waste.

A scrap from a carbon steel metal that is cylindrical will work best. Such include the sawmill cutting blade.

Step 2: Marking Dimensions

Use a metal marker pen to mark dimensions on the metal piece with a standard blade length of 5.6” and blade width of 2.2”.

Step 3: Cutting the Metal Along the Markings

Cut the metal along the markings using an angle grinder. Be sure to cut while leaving a margin for smoothening the edges.

Wear goggles and gloves while cutting for protection purposes.

Step 4: Put the Workpiece in a Furnace

Place the cut workpiece in the furnace until red hot. Heating makes the metal brittle, thus easier to forge and cut into the desired shape.

Step 5: Designing the Handle

With the Serbian chef knife being heavy,thehandlemust be strong. Cut the handle out using a chisel and a hammer while the metal is still red hot to assume the desired shape.

Step 6: Cutting the Worn-Out Edges

With repeated hammering, there is a need to cut the unwanted parts off using a chisel and a hammer on the red-hot metal. Be quick to cut before the metal gets cold.

Step 7: The Cutting Edge

The cutting edge is a crucial part of the blade since it determines the sharpness of the blade at the final stage.

Put the blade in the furnace with the cutting edge in contact with the fire till it’s red hot. Hold it using tongs and hammer the edge, peening the metal to assume a sharp thinner edge.

Once the cutting edge has been designed, the knife is ready for sharpening using a belt grinder.

Step 8: Branding the Blade

Branding involves inserting a permanent mark on the upper part of the blade for identification. Use a rivet with the desired logo.

Step 9: Tempering

Tempering involves hardening the blade by heating under high temperatures then cooling suddenly with water.

At this stage, you can dip the blade in a mixture of sodium cyanide salts to remove the rust on the blade. Scrap off the dirt and the remaining rust through filling and grinding the surfaces.

Filling gives a smooth, shiny appearance to the blade. The extent of shininess depends on your desire.

Step 10: Shaping the Edges and Sharpening the Cutting Blade

Finally, the blade is filed to achieve smooth edges and sharpen the cutting edge.

Step 11: Designing of the Metal Ring

It is likely for the wooden handle to slide with time, which may cause injury while using the knife. To avoid that, we fix a metal ring at the base of the handle, which is firmly attached to the handle.

The metal ring is designed by cutting a piece with equal edge dimensions as the handle for perfect fitting. Drill the metal piece in the middle to allow the blade to fit firmly.

Step 12: Preparing a Wooden Handle

The Serbian chef knives are quite heavy to handle, and hence a good handle would go a big deal in giving a firm, strong and comfortable grip.

For an ideal handle, bore a hole on a block piece of wood at the Center. The hole should be narrow to allow for tight fixation of the handle.

Heat the handle till it’s red hot and force its way into the wood. Drill a hole midway of the length of the handle

Step 13: Making Rivets and Riveting

Cut rivets from aluminum metal. Rivet the aluminum through the handle, cutting the excess pieces. Polish the handle with sandpaper to smoothen the edges.

Step 14: Sharpening and Smoothening the Blade

The blade can be sharpened and filed to the desired smoothness with the handle in place. The blade is now ready for use.

You can purchase a leather sheath to protect the blade when it’s not being used.

Tips To Maintain Handmade Serbian Knife

Making Serbian chef knives is a time consuming process that would pain you when the blade or handle gets damaged. Therefore, the knife needs to be maintained to keep it in good condition.

Since the knife is made of a high carbon blade, it is susceptible to rust and needs to be cleaned regularly.

When storing for a long period, it’s prudent to apply food-safe oil to prevent rusting. Serbian knives are heat treated hence brittle; they may require care when handling to avoid breakage.

As you have seen in the making process, the handle is important. When washing, care, and maintenance are needed, dry the handle, especially wooden ones, to avoid damages.

How Much Does The Handmade Serbian Knife Cost?

The Serbian knife varies in cost due to various factors such as the size, design, purpose of the knife.

Some designs and methods of forging may see the price rise up to around 150$, while others may be as low as 19$. On average a serbian knife will cost you 100$.

The prices are negotiable while others are fixed. The bottom line is that there is a Serbian chef knife for your pocket value.

However, the higher the price, the more durable and authentic the knife is.

It’s important that as you purchase the Serbian knives, you are keen only to buy the authentic Serbian hand forged knife and not a copy.

BEFORE you buy the serbian handmade knife, hold it in your hand and make sure it naturally fits you.

Advantages Of Using A Serbian Handmade Knife

The Serbian knife set comes with a package of good features that you would highly consider when buying a knife. Some of the outstanding features of the Serbian chef knives are:

- Durable and strong as it is made from carbon steel.

- It’s multipurpose

- Unique design

- Hand Forged

- Long-lasting sharpness

- It comes with a leather pocket for easier storage

Conclusion

It’s clear that with this guide(step-by-step), the process for making your custom hand-forged knife is easy.

It’s also evident that Serbian chef knives are handmade.

From the list of advantages associated with the Serbian knife, it’s enough to say that a knife is a necessary tool if not a must-have in your kitchen cutleries.

You are carrying out the maintenance practices to have a durable yet efficient knife for your all-purpose activities, so make it a habit.

Take into consideration the precautions indicated to avoid injuries and burns.